As our world has continued to develop, we have increasingly covered it with hard surfaces such as pavements, roads and car parks. The majority of these historically have been impermeable, and when combined with poor maintenance and increased rainfall events has led to widespread flooding…but what if all these surfaces could be permeable?

Welcome to our next instalment of our deep dive into the world of Sustainable Drainage Systems (SuDS) where this week we are going to look at how we can use pervious paving systems as part of our drainage strategies.

OK so what is Pervious Paving?

In simple terms a pervious paving system is a pavement which can still accommodate pedestrians and traffic but has the ability to allow water to infiltrate through its surface before being temporarily stored and discharged.

There are two types of pervious systems and which one you go for really depends on the finish you want for your site and the anticipated loadings.

The first is a Porous Pavement which allows water to infiltrate across the entire surface. This commonly takes the form of porous asphalt or concrete, but can also include gravel and reinforced grass surfaces.

The second system is Permeable Pavements which generally people are much more familiar with. In comparison to the porous system, the majority of the surface is made up of impermeable material such as concrete blocks, however, they are laid to permit water to pass in the void space between them allowing water to get into the sub-base.

Figure 1: Examples of Porous (left) and Permeable (right) pavements

So once we have got water off the surface what happens then?

What happens once water has entered the subbase of the pavement really depends on your ground conditions.

If they are good with a high permeability rate and no contaminants it is likely a Type A system would be used. This temporarily stores water before it is infiltrated into the soil beneath. The advantage of this system is that there is usually no requirement for a connection into a sewer or watercourse, however, you may need to install an emergency overflow to ensure the adequate provision for extreme rainfall events.

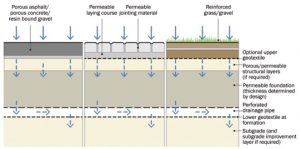

Figure 2: Type A (Total infiltration) Pervious Paving System

Source: CIRIA SuDS Manual C753 v6

If ground conditions are not as permeable but there is still no contamination than a partial infiltration, Type B, system can be specified. In this system once water has entered the subbase it first has the opportunity to infiltrate into the soil beneath, however, once it is at capacity water can then be conveyed into the main drainage system through either a pipe or geocomposite layer.

Figure 3: Type B (Partial Infiltration) pervious paving system

Source: CIRIA SuDS Manual C753 v6

The final system, Type C, should be used where the receiving soil has a low permeability, is contaminated or there are potential groundwater issues. This system allows for no infiltration, and instead lines the subbase with an impermeable membrane. Water then filters through the sub-base, which maintains treatment, before it is conveyed using a perforated pipe into the main system.

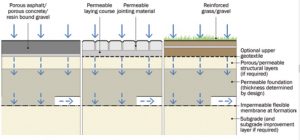

Figure 4: Type C (no infiltration) Pervious Paving System

Source: CIRIA SuDS Manual C753 v6

Can I use a pervious paving system on any type of development?

Depending on the type of system selected, the opportunities for incorporating a pervious paving system into your development are endless.

For lightly trafficked areas such as overflow car parks, private driveways and schools, a porous asphalt or grass reinforcement system could be used.

If a system is required to take larger loads, such as for a port, it may be preferable to use a modular permeable paving system instead.

Some common myths…busted!

There are many benefits to installing a pervious paving system on a development, however, as a designer I still often get clients who have some real concerns about switching to a pervious approach.

To try and get to the bottom of this I caught up with Chris Griffiths who is the Engineering Marketing Manager at Marshalls plc which are the UK’s leading hard landscaping manufacturer. Chris has a wealth of knowledge on permeable paving, so I asked him what he believed the three biggest myths associated with permeable paving were – and then more importantly to explain why they were not true. This was what Chris has to say.

The most common myth we see is that when permeable paving gets clogged up it stops working?

This is not the case! What actually happens in normal use, is that over time dust and debris settle in the joints which make them appear blocked. In reality this debris creates just a thin crust maybe 4mm or 5mm thick over the top of the joint. Water soaks through this quickly and easily – so although a permeable block pavement may appear blocked, and although the infiltration rate will be reduced, it will still be more than permeable enough to cope with UK rainfall events.

Myth number two is that it’s difficult to maintain a permeable pavement system

Again no. Under normal conditions, a permeable pavement will work perfectly well with no maintenance whatsoever, but if it does need cleaning, it’s a very simple process – certainly no more onerous than jetting a traditional pipe and gulley system!

The final most common objection is the belief that soft SuDS are better at cleansing water runoff than permeable pavements?

It’s widely accepted that swales, reed beds and other soft SuDS features are excellent at cleansing runoff. Back in 2014, there was no information about what effect a permeable pavement might have on water quality – so we commissioned large-scale test with Coventry University to find out.

What we discovered was that the sub-base of a permeable pavement cleanses water in two ways. Firstly, as water makes its tortuous route through the system, solids are mechanically filtered out. There’s also a biological cleansing process going on, as microbes “eat” pollutants in the water as it passes through. The majority of this process takes place in the top 50mm of the pavement (where oxygen levels are high, and therefore microbial activity is highest) – so it doesn’t make any difference how deep the system is.

The net result is that when we simulated significant oil spills on our test rigs, in most of the tests the discharge was of sufficient quality to pass WHO quality standards. We can safely say that a permeable pavement provides a controlled flow of clean water!

Summary

A pervious paving system, whether permeable or porous can bring a range of benefits to a site and used in the right location can play a critical part in meeting your attenuation requirements.

If you want to know more Chris has kindly provided a link to the Marshalls SuDS & Permeable Paving page (https://www.marshalls.co.uk/commercial/permeable-paving-and-suds) or why not get in touch with us here at Rennard Consulting Limited where we will be happy to talk through how a pervious paving system could be used on your project.